產(chǎn)品介紹

閥桿螺母

閥桿螺母的材料完全符合API標(biāo)準(zhǔn),可耐高溫,抗腐蝕能力強(qiáng)。

螺栓連接

栓接閥桿的制造嚴(yán)格按照API600標(biāo)準(zhǔn)規(guī)范。螺母的制造嚴(yán)格按照ANSI B1.1標(biāo)準(zhǔn)規(guī)范。

栓接螺母,六角形, 剛性,熱鍛,制造嚴(yán)格按造標(biāo)準(zhǔn)ANSI B 18.2.2.

閥蓋

閥蓋和閥體壁厚相同與支架連接或分開(kāi).體蓋連接法蘭的孔口平面能與螺栓螺母完全吻合.

當(dāng)閥門(mén)全開(kāi)時(shí)可以更換填料,閥桿填料函尺寸嚴(yán)格按照API標(biāo)準(zhǔn)執(zhí)行.

閥桿

單片結(jié)構(gòu)的閥桿表面經(jīng)過(guò)熱處理,硬度良好。頭部呈圓形且表面經(jīng)過(guò)拋光處理,可降低其與閥板接套之間的摩擦。

閥板

閥板可隨閥桿自由轉(zhuǎn)動(dòng),當(dāng)關(guān)閉閥門(mén)時(shí)可減小與閥座之間的摩擦。閥板鍛造并經(jīng)過(guò)磨圓,鏡面拋光,熱處理和硬度調(diào)整。

閥體

鑄鋼閥體的壁厚高于API600的最低標(biāo)準(zhǔn)要求.通口和閥座尺寸按照ANSI B 16.5 的管件標(biāo)準(zhǔn)要求設(shè)計(jì)。可更換閥座,體蓋連接為內(nèi)外螺紋副,閥體中心為橢圓形可增加中腔壁厚, 承壓力能力亦隨之增強(qiáng)。

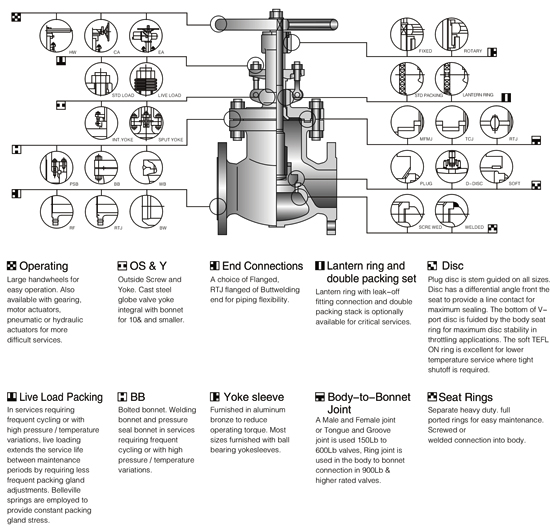

Design

JINGJIA cast steel globe valve are designed and manufactured to provide maximum service life and dependability. All globe valves are full ported and meet the design requirements of American Petroleum Institute Standard API 600 & API 6D, BS EN 13709 and generally conform to American Society complete range of body/bonnet materials and trims.

Rang of Materials

Standard body/bonnet materials include nine grades of carbon, low alloy and stainless steels, For special apolications they can be supplied in other grades of alloy and stainless steell, There′s′a full range of trim materials to match any service. Optional packing and gasket materials are available for a full range of service conditions.

Available Modifications for JINGJIA Cast Steel Valves

* Trim Changes

* End Connection Modifications

* Packing and Gasket Changes

* Operator Mounting

* Handwheel Extensions

* Pressure Equalizing

* By-pass

* Customer Specified Coatings

* Weld End Bore Changes

* Oxygen & Chlorine Cleaning & Packaging

Standard Material Specifiactions

| NO. |

Part Name |

ASTM Material |

| Carbon steel |

1.25Cr-0.5Mo |

2.25Cr-1Mo |

304 Type |

316 Type |

304L Type |

316L Type |

20 Alloy |

| 1 |

Body |

A216 WCB?

|

A217 WC6 |

A217 WC9 |

A351 CF8 |

A351 CF8M |

A351 CF3 |

A351 CF3M |

A351 CN7M |

| 2 |

Bonnet |

A216 WCB |

A217 WC6 |

A217 WC9 |

A351 CF8 |

A351 CF8M |

A351 CF3 |

A351 CF3M |

A351 CN7M |

| 3 |

Disc |

WCB+13Cr *1 |

A217 WC6+HF |

A217 WC9+HF |

A351 CF8 |

A351 CF8M |

A351 CF3 |

A351 CF3M |

A351 CN7M |

| 4 |

Stem |

A182 F6a |

A182 F11 |

A182 F22 |

A182 F304 |

A182 F316 |

A182 F304L |

A182 F316L |

20-Alloy |

| 5 |

Seat Ring |

A105+13Cr *1 |

A182 F11+HF |

A182 F22+HF |

NA |

NA |

| 6 |

Back Seat |

A276 410 |

A276 410 |

A276 410 |

NA |

NA |

| 7A |

Bonnet Gasket |

304+graphite |

304+graphite |

304+graphite |

304+graphite |

316+graphite |

304L+graphite |

316L+graphite |

316+graphite |

| 7B |

Ring Gasket |

Soft steel |

A182 F304 |

A182 F304 |

A182 F304 |

A182 F316 |

A182 F304L |

A182 F316L |

20/Alloy |

| 8 |

Bonnet Bolt |

A193 B7 |

A193 B7 |

A193 B16 |

A193 B8 |

A193 B8M |

A193 B8 |

A193 B8M |

A193 B8M |

| 9 |

Bonnet Nut |

A194 2H |

A194 7 |

A194 7 |

A194 8 |

A194 8M |

A194 8 |

A194 8M |

A194 8M |

| 10 |

Packing |

Graphite |

Graphite |

Graphite |

Graphite *2 |

Graphite *2 |

Graphite *2 |

Graphite *2 |

Graphite *2 |

| 11 |

Gland |

A276 410 |

A276 410 |

A276 410 |

A276 304 |

A276 316 |

A276 304L |

A276 316L |

20/Alloy |

| 12 |

Gland Flange |

A216 WCB |

? |

? |

A351 CF8 |

A351 CF8 |

A351 CF8 |

A351 CF8 |

A351 CF8 |

| 13 |

Eyebolt |

Carbon steel |

A193 B7 |

A193 B7 |

A193 B8 |

A193 B8 |

A193 B8 |

A193 B8 |

A193 B8 |

| 14 |

Eyebolt Nut |

Carbon steel |

A194 2H |

A194 2H |

A194 8 |

A194 8 |

A194 8 |

A194 8 |

A194 8 |

| 15 |

Eyebolt Pin |

A276 410 |

A276 410 |

A276 410 |

A276 304 |

A276 304 |

A276 304 |

A276 304 |

A276 304 |

| 16 |

Yoke Sleeve |

Bronze |

Bronze *3 |

Bronze *3 |

Bronze |

Bronze |

| 17 |

Hand Wheel |

Malleable iron |

Malleable iron |

Malleable iron |

| 18 |

Wheel Nut |

Carbon steel |

Stainless steel |

Stainless steel |

| *1 |

PN≥600 CLASS seal face will be HF |

| *2 |

PTFE Optional |

| *3 |

Ductile Ni-Resist iron Optional |

| NA |

tegral with vessell |

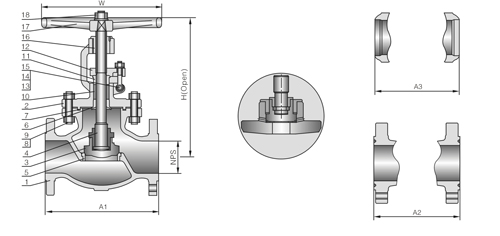

主要外觀尺寸和重量?Class 150/10K

| Valve Size |

in |

2 |

2.5 |

3 |

4 |

6 |

8 |

10 |

12 |

14 |

16 |

18 |

| mm |

50 |

65 |

80 |

100 |

150 |

200 |

250 |

300 |

350 |

400 |

450 |

| A1&A3 |

in |

8.0 |

8.5 |

9.5 |

11.5 |

16.0 |

19.5 |

24.5 |

27.5 |

31.0 |

36.0 |

38.5 |

| mm |

203 |

216 |

241 |

292 |

406 |

495 |

622 |

698 |

787 |

914 |

978 |

| H |

in |

15.3 |

14.8 |

17.0 |

19.5 |

22.6 |

28.0 |

31.4 |

39.1 |

54.6 |

53.4 |

78.0 |

| mm |

383 |

376 |

433 |

495 |

574 |

710 |

797 |

992 |

1387 |

1356 |

1980 |

| W |

in |

7.9 |

8.8 |

8.8 |

9.8 |

14.0 |

14.0 |

17.7 |

17.7 |

22.0 |

220 |

240 |

| mm |

200 |

224 |

224 |

250 |

355 |

355 |

450 |

450 |

560 |

560 |

610 |

| Weight |

RF |

ib |

44.1 |

77.2 |

88.2 |

123.5 |

229.3 |

401.3 |

650.5 |

904 |

1510 |

1985 |

39690 |

| kg |

20 |

35 |

40 |

56 |

104 |

182 |

295 |

410 |

685 |

900 |

1800 |

| BW |

ib |

33.1 |

66.2 |

70.6 |

90.4 |

183.0 |

330.8 |

496.1 |

728 |

1312 |

1764 |

3638.3 |

| kg |

15 |

30 |

32 |

41 |

83 |

150 |

225 |

330 |

595 |

800 |

1650 |

主要外觀尺寸和重量Class 300/20K

Valve

Size |

in |

2 |

2.5 |

3 |

4 |

6 |

8 |

10 |

12 |

14 |

16 |

| mm |

50 |

65 |

80 |

100 |

150 |

200 |

250 |

300 |

350 |

400 |

| A1&A3 |

in |

10.5 |

11.5 |

12.5 |

140 |

17.5 |

220 |

24.5 |

28.0 |

39.0 |

42.0 |

| mm |

267 |

292 |

318 |

356 |

444 |

559 |

622 |

711 |

991 |

1067 |

| A2 |

in |

11.12 |

12.12 |

13.12 |

14.62 |

18.12 |

22.62 |

25.12 |

28.62 |

39.62 |

42.62 |

| mm |

283 |

308 |

333 |

371 |

460 |

575 |

638 |

727 |

1006 |

1083 |

| H |

in |

15.6 |

16.3 |

18.2 |

21.7 |

29.2 |

31.5 |

446 |

46.1 |

56.5 |

70.7 |

| mm |

396 |

415 |

462 |

550 |

741 |

300 |

1132 |

1172 |

1435 |

1797 |

| W |

in |

7.9 |

8.8 |

9.8 |

140 |

17.7 |

22.0 |

220 |

28.0 |

28.0 |

31.5 |

| mm |

200 |

224 |

250 |

355 |

450 |

560 |

560 |

710 |

710 |

800 |

| Weight |

RF |

ib |

70.6 |

92.6 |

141.0 |

220.5 |

419.0 |

595.4 |

1163.7 |

2240 |

2546.8 |

3748.5 |

| kg |

32 |

42 |

64 |

100 |

190 |

270 |

530 |

1016 |

1155 |

1700 |

| BW |

ib |

66.2 |

66.2 |

105.89 |

194.0 |

328.5 |

441 |

970.2 |

1997.7 |

2216 |

3309.7 |

| kg |

30 |

30 |

48 |

88 |

149 |

200 |

440 |

906 |

1005 |

1501 |

主要外觀尺寸和重量?600/40K

Valve?

Size |

in |

2 |

2.5 |

3 |

4 |

6 |

8 |

10 |

12 |

14 |

16 |

| mm |

50 |

65 |

80 |

100 |

150 |

200 |

250 |

300 |

350 |

400 |

| A1&A3 |

in |

11.5 |

13.0 |

14.0 |

17.0 |

22.0 |

26.0 |

31.0 |

33.0 |

35.0 |

39.0 |

| mm |

292 |

330 |

356 |

432 |

559 |

660 |

787 |

818 |

889 |

991 |

| A2 |

in |

11.62 |

13.12 |

14.12 |

17.12 |

22.12 |

26.12 |

31.12 |

33.12 |

35.12 |

39.12 |

| mm |

295 |

333 |

359 |

435 |

562 |

664 |

792 |

841 |

892 |

994 |

| H |

in |

16.0 |

19.8 |

19.9 |

22.4 |

29.9 |

51.8 |

59.5 |

69.9 |

70.9 |

76.0 |

| mm |

407 |

502 |

505 |

165 |

759 |

1315 |

1511 |

1775 |

1800 |

1930 |

| W |

in |

8.8 |

9.8 |

11.0 |

14.0 |

17.7 |

28.0 |

31.5 |

35.4 |

35.4 |

35.4 |

| mm |

224 |

250 |

280 |

355 |

450 |

710 |

800 |

900 |

900 |

900 |

| Weight |

RF |

ib |

94.8 |

154.4 |

172.0 |

300.0 |

619.6 |

1301 |

2099 |

3528 |

5953.5 |

7938.0 |

| kg |

43 |

70 |

78 |

136 |

281 |

590 |

952 |

1600 |

2700 |

3600 |

| BW |

ib |

72.8 |

121.3 |

132.3 |

216.1 |

454.2 |

1125 |

1746 |

3263.45 |

5534.6 |

7386.8 |

| kg |

33 |

55 |

60 |

98 |

206 |

510 |

792 |

1480 |

2510 |

3350 |

主要外觀尺寸和重量Class 900

Valve

Size |

in |

2 |

2.5 |

3 |

4 |

6 |

8 |

10 |

12 |

14 |

16 |

| mm |

50 |

65 |

80 |

100 |

150 |

200 |

250 |

300 |

350 |

400 |

| A1&A3 |

in |

14.5 |

16.5 |

15.0 |

18.0 |

24.0 |

29.0 |

33.0 |

38.0 |

40.5 |

44.5 |

| mm |

368 |

419 |

381 |

457 |

610 |

737 |

838 |

965 |

1029 |

1130 |

| A2 |

in |

14.62 |

16.62 |

15.12 |

18.12 |

24.12 |

29.12 |

33.12 |

38.12 |

40.88 |

44.88 |

| mm |

371 |

422 |

384 |

460 |

613 |

740 |

841 |

968 |

1038 |

1140 |

| H |

in |

27.4 |

27.3 |

30.5 |

33.7 |

50.7 |

65.6 |

63.0 |

67.1 |

87.0 |

103.1 |

| mm |

695 |

695 |

77.5 |

855 |

1288 |

1665 |

1600 |

1705 |

2210 |

2620 |

| W |

in |

15.7 |

15.7 |

15.7 |

15.7 |

22.0 |

31.5 |

31.5 |

35.4 |

35.4 |

35.4 |

| mm |

400 |

400 |

400 |

400 |

560 |

800 |

800 |

900 |

900 |

900 |

| Weight |

RF |

ib |

271.2 |

341.8 |

231.5 |

441 |

1101.5 |

2756.3 |

4520.3 |

5843.3 |

8048.3 |

9481.5 |

| kg |

123 |

155 |

105 |

200 |

500 |

1250 |

2050 |

2650 |

3650 |

4300 |

| BW |

ib |

205.1 |

264.6 |

196.2 |

335.2 |

903.2 |

2425.5 |

4123.4 |

5292.0 |

7386.8 |

8600.0 |

| kg |

93 |

120 |

89 |

152 |

410 |

1100 |

1870 |

2400 |

3350 |

3900 |

主要外觀尺寸和重量Class 1500

Valve

Size |

in |

2 |

2.5 |

3 |

4 |

6 |

8 |

10 |

12 |

14 |

16 |

| mm |

50 |

65 |

80 |

100 |

150 |

200 |

250 |

300 |

350 |

400 |

| A1&A3 |

in |

14.5 |

16.5 |

18.5 |

21.5 |

27.75 |

32.75 |

39.0 |

44.5 |

49.5 |

54.5 |

| mm |

368 |

419 |

470 |

546 |

705 |

832 |

991 |

1130 |

1257 |

1384 |

| A2 |

in |

14.62 |

16.62 |

18.62 |

21.62 |

28.0 |

33.13 |

39.38 |

45.12 |

50.25 |

55.38 |

| mm |

371 |

422 |

473 |

549 |

711 |

841 |

1000 |

1146 |

1276 |

1407 |

| H |

in |

27.4 |

27.3 |

31.5 |

40.0 |

53.0 |

77.2 |

91.0 |

105.1 |

126.0 |

160.0 |

| mm |

695 |

695 |

799 |

1015 |

1345 |

1960 |

2310 |

2670 |

3200 |

4064 |

| W |

in |

15.7 |

15.7 |

19.7 |

19.7 |

28.0 |

28.0 |

30.0 |

30.0 |

30.0 |

30.0 |

| mm |

400 |

400 |

500 |

500 |

710 |

710 |

760 |

760 |

760 |

760 |

| Weight |

RF |

ib |

271.2 |

341.8 |

396.9 |

749.7 |

1482 |

4630.5 |

7056.0 |

9702.0 |

11907.0 |

14773.5 |

| kg |

123 |

155 |

180 |

340 |

672 |

2100 |

3200 |

4400 |

5400 |

6700 |

| BW |

ib |

205.1 |

264.6 |

297.7 |

621.8 |

12171 |

4190.0 |

6174.0 |

8379.0 |

10363.5 |

12789.0 |

| kg |

93 |

120 |

135 |

282 |

552 |

1900 |

2800 |

3800 |

4700 |

5800 |

主要外觀尺寸和重量Class 2500

Valve

Size |

in |

2 |

2.5 |

3 |

4 |

6 |

8 |

10 |

12 |

| mm |

50 |

65 |

80 |

100 |

150 |

200 |

250 |

300 |

| A1&A3 |

in |

17.75 |

20.0 |

22.75 |

26.5 |

36.0 |

40.25 |

50.0 |

56.0 |

| mm |

451 |

508 |

578 |

673 |

914 |

1022 |

1270 |

1422 |

| A2 |

in |

17.87 |

20.25 |

23.0 |

26.88 |

36.5 |

40.87 |

50.88 |

56.88 |

| mm |

454 |

514 |

584 |

683 |

927 |

10.38 |

1292 |

1445 |

| H |

in |

28.3 |

31.5 |

34.8 |

50.0 |

75.0 |

97.0 |

110.2 |

138.0 |

| mm |

720 |

800 |

885 |

1260 |

1905 |

2465 |

2800 |

3505 |

| W |

in |

15.7 |

19.7 |

19.7 |

24.0 |

24.0 |

30.0 |

30.0 |

30.0 |

| mm |

400 |

500 |

500 |

610 |

610 |

760 |

760 |

760 |

| Weight |

RF |

ib |

419.0 |

661.5 |

771.8 |

1852.2 |

5071.5 |

105840 |

14994.0 |

18742.5 |

| kg |

190 |

300 |

350 |

840 |

2300 |

4800 |

6800 |

8500 |

| BW |

ib |

352.8 |

529.2 |

617.4 |

1521.5 |

4410.0 |

9702.0 |

13230.0 |

16537.5 |

| kg |

160 |

240 |

280 |

690 |

2000 |

4400 |

6000 |

7500 |